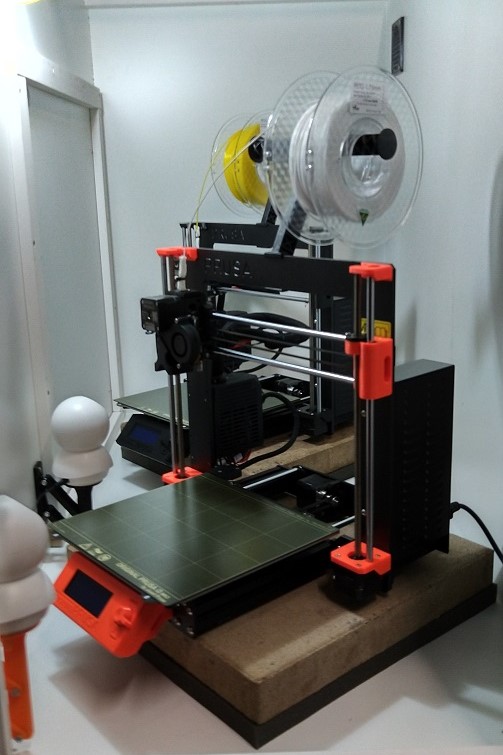

The 3D printing enclosure has been a work in progress for the past few months as more upgrades have been added to further improve print quality and safety.

The addition of cameras and WIFI controlled power switches mean that long prints can be monitored and stopped from anywhere in the world if something isn’t right. When trying out new filaments, it is wise to stop a test print short if it doesn’t like a certain speed or temperature setting.

Other improvements are the concrete pavers and foam blocks underneath each printer that act as a damper to prevent vibrations affecting print quality. A cheap and simple upgrade that makes quite a difference.

Lastly, an air purifier has been ordered to extract any fumes building up in the workshop. Future plans to experiment with ABS and ASA filaments require this as the fumes released by printing with them are toxic to people and the environment. I’d rather keep them out of the atmosphere!